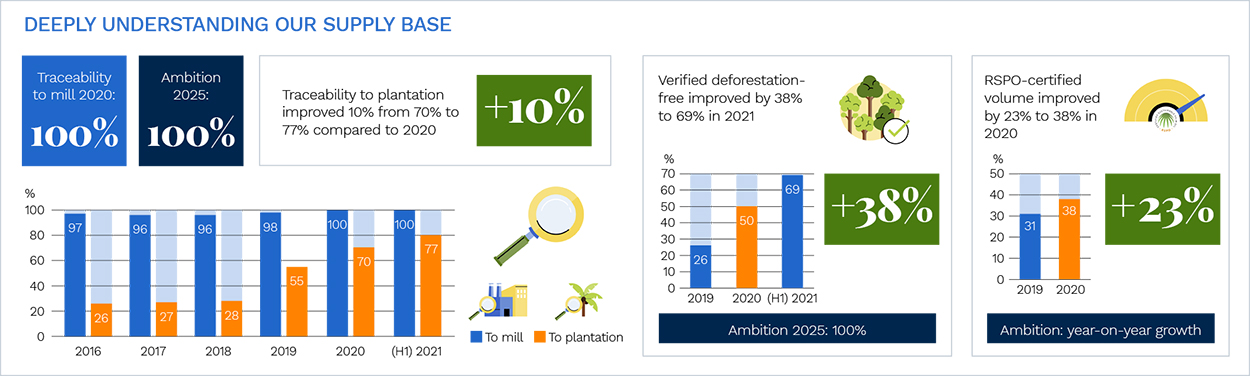

AAK continued to make strong progress within its palm oil supply chain during the first half-year of 2021, lifting traceability to plantation by 10 percent and verified deforestation-free volumes by 38 percent – major steps towards reaching key targets. The strong progress reported coincides with the encouraging commitment from global leaders at COP26 in Glasgow to halt and reverse forest loss and land degradation by 2030.

As one of the world’s leading manufacturers of speciality oils and fats solutions, palm is a key plant-based ingredient for AAK. Delivering sustainable palm-based products from both certified and conventional sources is key to the company’s commitment and success.

Last year, AAK announced its commitment to a palm oil supply chain that is 100 percent verified deforestation-free and 100 percent traceable to plantation by 2025. Between January and June, traceability to planation increased from 70 to 77 percent (up 10 percent) compared to 2020, while verified deforestation-free volumes increased from 50 to 69 percent (up 38 percent).

“We are very proud of our strong progress”, says Caroline Westerik-Sikking, Global Manager Sustainable Oils at AAK. “These results have been enabled by a program of committed supplier engagement, technology and specialist support, and by a further strengthened AAK sustainability team.”

Important metrics to address deforestation

Traceability to plantation (TTP) is a basic requirement to understand risks within the supply base. Collaboration and transparency between companies in the sector has improved greatly over recent years, facilitating data-sharing and, in some cases, removing the burden of double work. In order to use TTP data to address deforestation, AAK earlier this year entered into partnerships with Earthqualizer and Satelligence who provide satellite monitoring of AAK’s global supply base.

“This has enabled us to have near real-time access to deforestation alerts which we can investigate through our suppliers”, says Jonathan Escolar, Global Sustainability Program Manager at AAK. “In addition to giving us a quick start to address potential issues and work on remediation plans, it has also provided a more nuanced understanding of land use changes in producer countries, many of which are not linked directly to palm production. This allows us to respond quickly, and with confidence, to concerned stakeholders, be it customers or NGOs.”

The detailed analysis of, and engagement with, AAK’s supply base has also improved the company’s scores on verified deforestation-free (VDF) palm oil. While not yet an industry standard metric, there are a number of companies reporting on it. TTP is an important criterion for establishing VDF scores, hence, the two targets are tightly linked.

Partnerships and industry engagement

AAK recognizes that to bring about transformative change in the palm oil sector, it is not sufficient to work through its own supply chain alone. Therefore, the company also supports projects that improve the sustainability of global palm production.

Examples include Forever Sabah, an initiative to achieve jurisdictional RSPO certification for smallholders in the Malaysian state of Sabah, and a project with Solidaridad to improve livelihoods for smallholder producers in Mexico. AAK also recently announced a partnership with Musim Mas and Nestlé to support some 1,000 smallholders in Aceh, Indonesia. Expected outcomes of the program are increased yields and earnings for the smallholders, reducing the incentive to encroach into protected areas.

Furthermore, AAK remains an active member of the Roundtable on Sustainable Palm Oil (RSPO), of which it is a co-founder, and the company is deeply involved in the Palm Oil Collaboration Group (POCG).

“We firmly believe that systemic change can only be brought about by strong collaboration between all actors in the supply chain”, says Caroline Westerik-Sikking. “This year, we have shown real progress towards our 2025 targets. Still, much remains to be achieved. That’s why we, in line with our company purpose, constantly work for continuous improvement, Making Better Happen from plant to brand.”